Understanding the Mechanics of Tool Magnetisers

May 18, 2023

There are few things as frustrating as a screw falling off the screwdriver when you are in the middle of a tricky project. Or when you are working with a tiny bolt, and it bounces off the workbench and vanishes. We’ve all been there.

Fortunately, there is a solution to these maddening moments — a mangetiser. This tool is a game-changer when it comes to safeguarding the loss of a sharp-pointed metal pin.

But what exactly is a magnetiser, and how does it work? Read on to delve into this invaluable weapon and explore its practical applications.

What Is a Tool Magnetiser?

A magnetiser is a specialised tool designed to magnetise or demagnetise metallic objects. These include:

- screws

- nut drivers

- wrenches

- and other small ferrous components

The basic structure of a magnetiser consists of a simple yet ingenious structure. Starting with the body made of durable plastic or other non-magnetic materials. It provides the housing and protection for the internal components.

Located within the body, next is the magnetic channel for magnetisation or demagnetisation. It is a narrow passage or slot where you can insert the screwdriver.

At the heart of the magnetiser lies a permanent magnet. This magnet is strategically positioned within the magnetic channel. This, in return, generates a strong magnetic field.

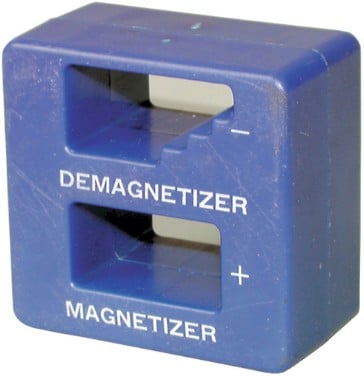

Magnetisers can convert any tool blade into a magnetic retrieval tool. This means you can make your regular screwdriver magnetic or nonmagnetic. This also allows you to demagnetise screwdrivers, nut drivers and wrenches. Have a look at this magnetiser for screwdrivers below:

Magnetizer for Screwdriver

Product code: JTD2042

This magnetiser has two slots, one for magnetising and the other for demagnetising. The holes are wide enough for the largest of screwdrivers.

The structure and working principle

A magnetiser harnesses the power of two strategically placed magnets with distinct properties. Here is a closer look at its unique structure and how it functions:

Within the tool, two magnets are positioned separately and mounted within a housing. The first magnet, situated above, is a permanent one with positive polarisation (+). The second magnet, located below and facing upwards, carries a negative charge (-). The former is designed for magnetising, while the latter is for demagnetisation purposes.

The two magnets face each other, causing them to repel or push away from one another. This arrangement plays a crucial role in the magnetising and demagnetising process. For instance, a screwdriver is inserted into the magnetiser. It will then interact with the magnetic fields generated by these opposing magnets.

Magnetisation Process

Here is a thorough explanation of the magnetisation process and its implications. To illustrate this process, consider the example of a screwdriver.

Magnetisation involves imbuing the screwdriver with magnetic properties. This allows it to attract and retain screws with enhanced efficiency and precision.

Within the magnetiser, a positive-polarised magnet takes centre stage. This magnet generates a magnetic field that interacts with the screwdriver. With this exposure, its internal magnetic domains align with the external magnetic field. And this alignment handles the magnetisation of the screwdriver.

Through the alignment of magnetic domains, the tool’s magnetic properties are amplified. This results in a stronger magnetic force, allowing it to hold the screws securely. In return, a magnetised screwdriver:

- provides a reliable grip on screws, reducing the chances of accidental drops or loss.

- simplifies the retrieval and precise placement of screws, saving valuable time and effort.

The magnetisation process is not permanent. You can reverse it using the same tool.

Demagnetisation Process

Demagnetisation removes or reduces the magnetic properties of a tool or object. This is accomplished by using a magnetiser, which operates on magnetic polarity. Here is how the demagnetisation process unfolds:

Demagnetisation is useful in scenarios where magnetised tools interfere with sensitive electronics. For instance, a magnetised screwdriver may pose a risk of damaging delicate circuitry. By demagnetising it, its magnetic properties are neutralised. This renders it safe for use in such applications.

Within the demagnetiser, a negative-polarized magnet comes into play. As the screwdriver is exposed to the magnetic field, its internal magnetic domains are disrupted. This causes the alignment of magnetic moments to become disordered. This disruption eliminates the screwdriver’s magnetic properties, rendering it non-magnetic.

In return, a demagnetised screwdriver:

- protects sensitive electronics and components from the potential risk of magnetic interference.

- ensures the smooth operation of magnetic devices.

The Practical Applications

Magnetisers find invaluable use in a wide range of scenarios and industries. Here are some practical applications that highlight the benefits of these tools:

Electronics and electrical work

- Magnetisers allow for aligning small metal components on circuit boards with precision. They also reduce the risk of damage to delicate electronic parts.

- Demagnetisers are crucial in electronic repair and maintenance. They prevent magnetic interference with sensitive electronic components. These can include hard drives, magnetic sensors, or medical equipment.

Automotive and mechanical engineering

- In such industries, magnetisers facilitate the retrieval and installation of metal fasteners. This improves efficiency during assembly or repair processes.

- Demagnetisers prevent unwanted attraction and interference when working on sensitive engine components. What’s more, on electronic systems or magnetic sensors in automotive applications.

Woodworking and carpentry

- Magnetisers ensure better control and handling of nails and screws. This reduces the risk of dropped or misplaced fasteners, improving efficiency.

- Demagnetisers prevent accidental attraction to metal objects and ensure clean, precise work.

Jewellery and watchmaking

- Magnetisers ease the handling and placement of small metal components like watch hands. They enable meticulous craftsmanship and ensure accurate assembly.

- Demagnetisers help eliminate magnetism in tools used in jewellery and watchmaking. This prevents damage to delicate components, particularly in watches and sensitive magnetic mechanisms.

Manufacturing and assembly lines

- Magnetisers enhance productivity and speed in manufacturing and assembly lines. They simplify the process of retrieving and aligning metal components. This leads to faster assembly and reduced errors.

- Demagnetisers eliminate magnetic interference that may impact the functionality of magnetic components. Or where it may disrupt the operation of automated systems on production lines.

These are just a few examples of practical applications that benefit from the use of this tool. By magnetising or demagnetising tools, professionals in various fields can improve efficiency, accuracy, and work quality.

The Bottom Line

If you often snoop electrical items apart, a magnetiser deserves a spot in your toolbox. It can help you get your project done faster and saves you a lot of headaches. Through the magnetism, screws sit firmly on the tool.

Even if you loosen a screw, the magnetic effect ensures it does not get lost after unscrewing. Meanwhile, if your work does not need a magnetic field, you can demagnetise your tool before use.

This article was originally published in June 2021 and has been updated.

© Electrotech Brands Pty Ltd 2023

Write a Comment

You must be logged in to post a comment.